From our brief consideration of the current technologies and the weighing of advantages and disadvantages, the universal advantages of etching technology become clear.

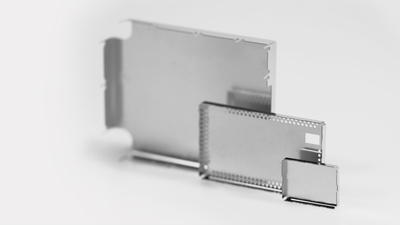

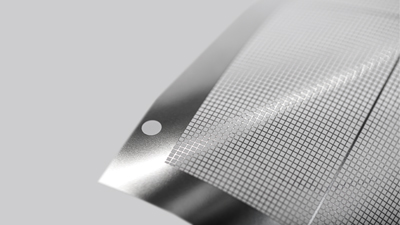

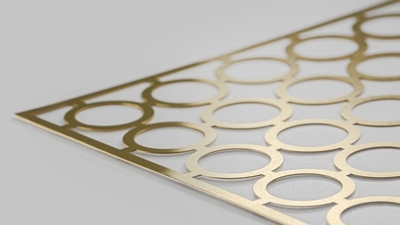

In the production of molded parts from sheet metal thicknesses of up to 1.5 mm and fine structuring, the precision, time savings and cost advantages of the etching technology or spray etching technology are unbeatable. The tools, i.e. the photo masks, can be created digitally and at very favorable conditions and adapted at any time – there are no additional tool costs.

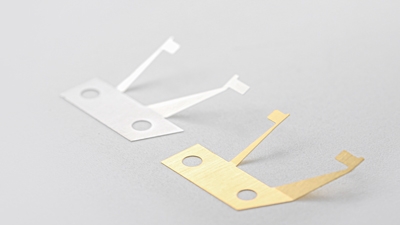

Since photochemical etching is suitable for a wide variety of metals and degrees of hardness, the choice of material has almost no influence on the level of costs. The short period of time between design and execution guarantees a quick and efficient implementation of pilot series. Clients benefit from the high flexibility in the case of short-term design changes or design adjustments.

A calculation per sheet opens up the possibility of accommodating different geometries on one sheet in a cost-saving manner. At the end of the etching process, there is a finished product which, due to the lack of burr formation on the workpiece edges, does not require any post-processing and in which the desired inscriptions or identifications may have already been applied in one pass during the etching.