Medical technology

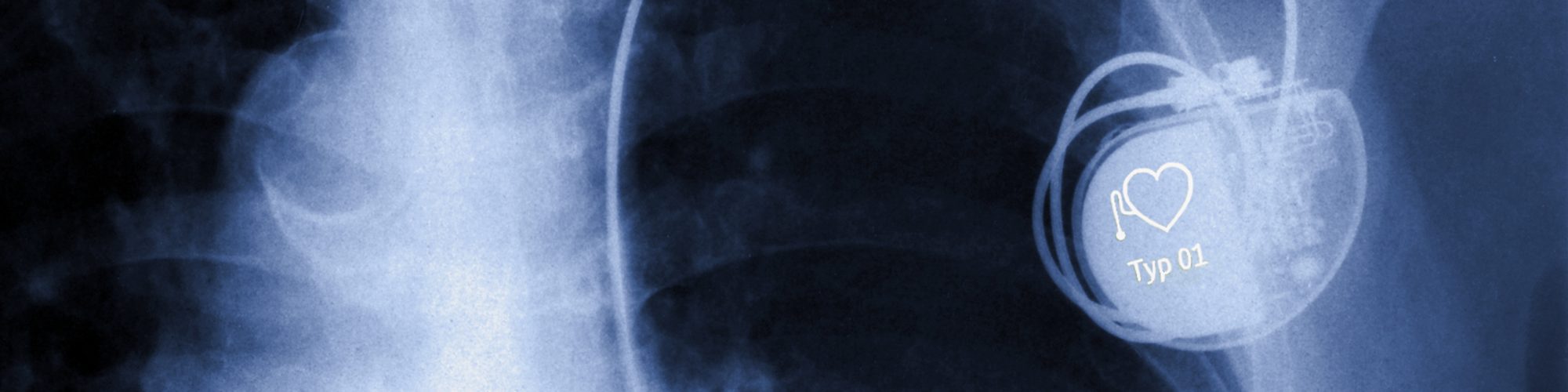

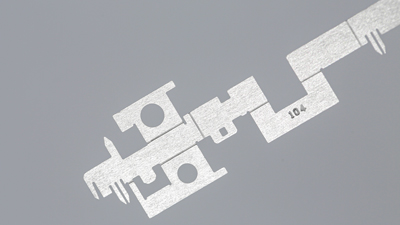

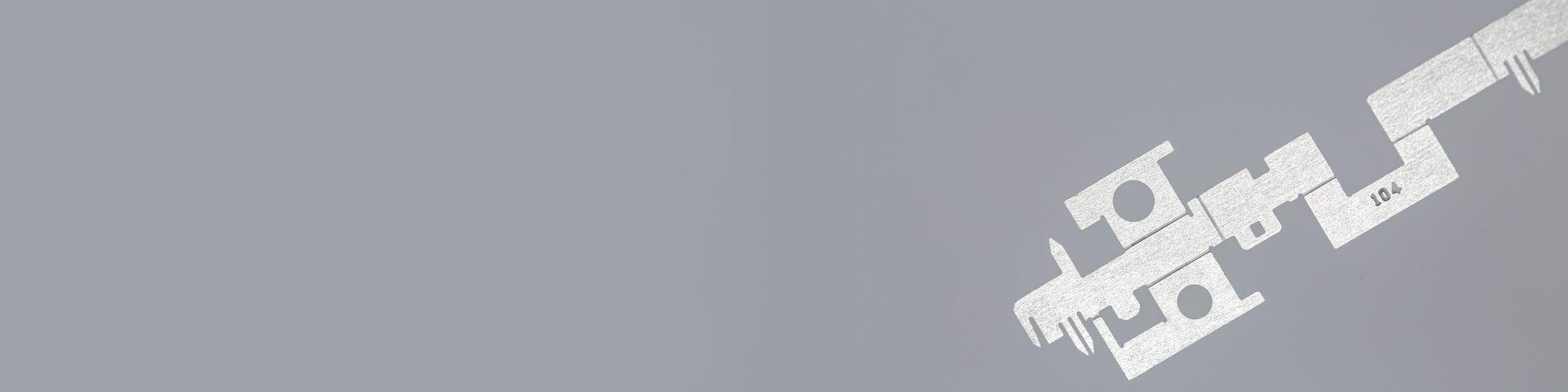

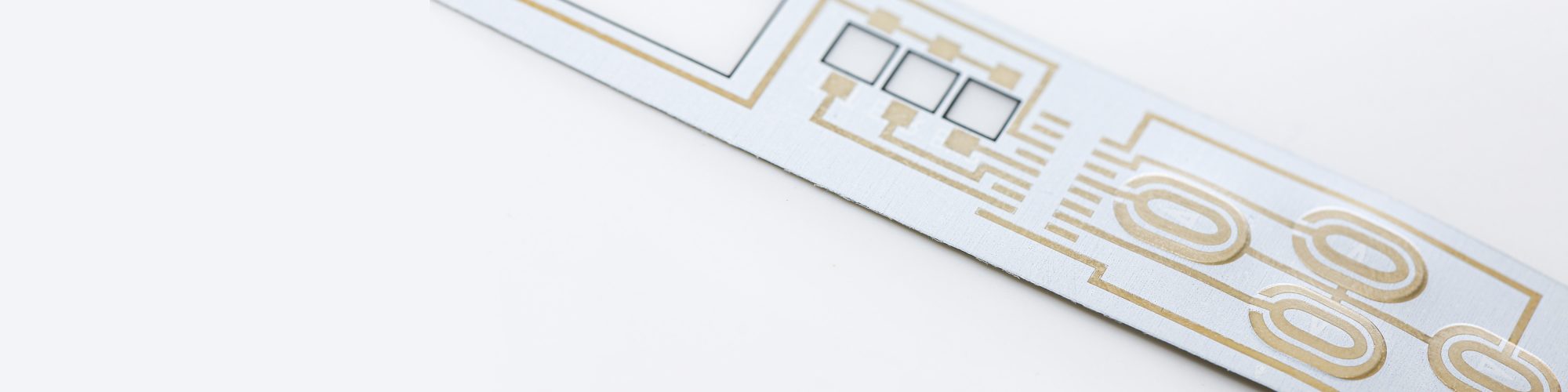

Our wide range of services in medicine extends from small precision etched parts for use in pacemakers to the printing of large housings – for example for sterilization devices.

Our special printing processes (screen printing, pad printing, digital printing / UV printing) enable the printing of medical products that meet the high medical requirements. For example, some printed images must be smudge-proof, scratch-proof and disinfectant-proof.